THE BARREL STAVE GUITAR

A friend who was opening a shop selling artefacts made from barrel staves (and there’s a vast array, from tables, chairs, and drinks cabinets to tea light holders) had a guitar stand arriving, made from barrel staves, of course. Before I’d even thought about it, I found myself suggesting that she would need a barrel stave guitar to sit on it. Thus a hornets nest of ideas, plans and a flurry of problem solving began to take shape in The Shed over the next few months . This is the result, “The Rollout” guitar, a prototype model.

Prototype of “The Rollout” Barrel Stave Guitar, constructed using whisky barrel stave top, arched ply back, five piece neck, barrel headstock with Steinberger tuners, Wilkinson P90 single coil pickup and bridge. Featuring “Bung” tone and volume knobs and a Bubinga fingerboard.

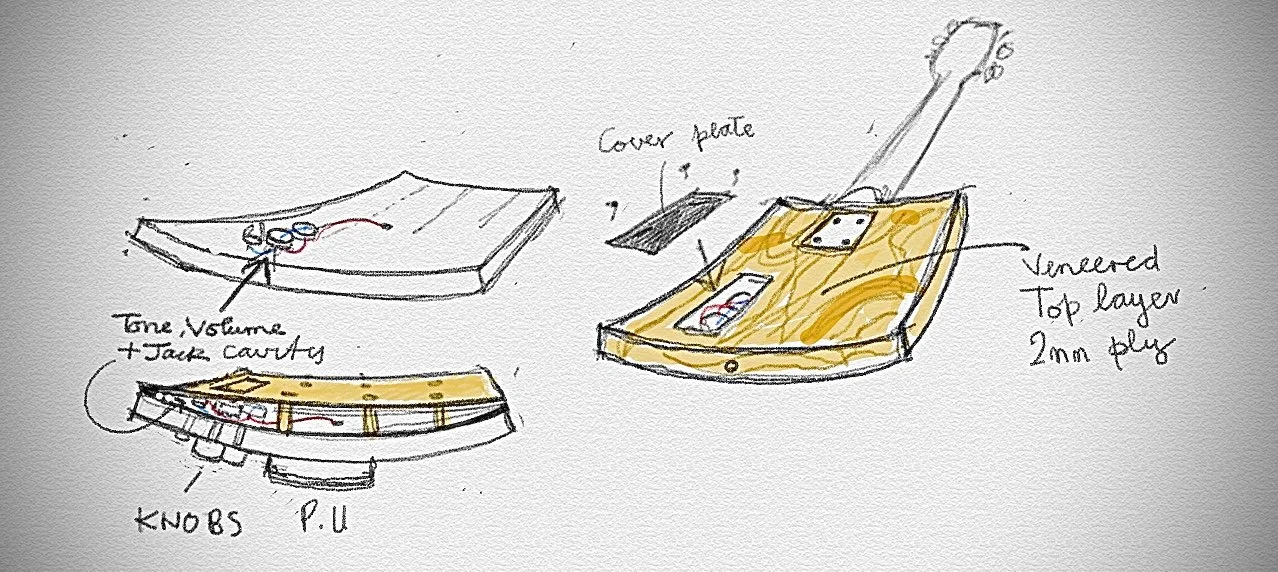

The back of the instrument is arched and bowed on two planes to maintain the barrel look, achieved by a double layer of ply, the first being pinned with dowels to hold the shape. Subsequent instruments will either be veneered or use a finer grade of wood. This is a rough sketch of how it worked out. After glueing the top staves together, the back was thinned down to loose a bit of weight. This left a rough surface, which could have been sanded back, but there would have been a problem with the exposed Tone and Volume circuit. various options were considered, including boxing . The solution presented itself when thinking about adding a finished piece of ply to the back, (to save all that sanding!) which, if not completely fixed to the back of the staves, but only attached to the edge, would result in a shallower curve, thus creating a cavity between the two surfaces. In order to stabilise the outer ply surface and stop it flexing, and provide a stable fixing point for a bolt on neck, a series of short dowels were inserted through holes drilled in the ply and glued in place. This proved a success and the back was now rigid.

Solving the problem of the exposed electrics on the back, by creating a cavity between the two surfaces by introducing a shallower curve in the ply back, which was then strengthened with dowling inserts, passed through pre- drilled holes. and glued top and bottom.